Carbon steel pipes are widely used in industrial and infrastructure applications due to their high strength and pressure-handling capability. Seamless pipes are manufactured without welding, offering superior performance in high-pressure and high-temperature environments. ERW pipes provide cost-effective solutions for structural and low-pressure applications. These pipes exhibit excellent mechanical strength, durability, and load-bearing capacity. Commonly used in oil & gas, power plants, refineries, and construction projects. Carbon steel pipes support fluid, gas, and steam transportation efficiently. Their adaptability makes them suitable for both above-ground and underground installations.

Stainless steel pipes are known for their exceptional corrosion resistance, hygiene, and durability. SS 304 is widely used for general industrial and commercial applications, while SS 316 offers enhanced resistance to chemicals and marine environments. These pipes perform reliably under high temperatures and pressure conditions. They are commonly used in food processing, pharmaceuticals, chemical plants, and water systems. Stainless steel pipes provide long service life with minimal maintenance. Their smooth internal surface ensures efficient flow and reduced contamination risk.

Galvanized iron (GI) pipes are steel pipes coated with zinc to protect against corrosion and rust. This coating enhances durability, making them suitable for water supply, plumbing, and outdoor applications. GI pipes offer good strength and resistance to environmental exposure. They are widely used in residential, commercial, and light industrial installations. These pipes ensure long-term performance in moderate pressure systems. Their ease of installation and availability make them a reliable piping solution.

Mild steel (MS) pipes are versatile and widely used for structural and low-pressure piping applications. Known for their strength, weldability, and cost-effectiveness, MS pipes are used in fabrication, construction, and industrial frameworks. They support fluid, gas, and air transportation in non-corrosive environments. MS pipes are easy to cut, bend, and weld, allowing flexible usage across projects. Common applications include scaffolding, structural supports, and mechanical systems. Their durability makes them suitable for both indoor and outdoor use with proper coating.

Copper pipes are preferred for their excellent thermal conductivity and corrosion resistance. Widely used in plumbing, HVAC, and refrigeration systems, they ensure efficient heat transfer. Copper pipes offer long service life and resistance to bacterial growth. Their flexibility allows easy installation in complex layouts. Suitable for hot and cold water supply, gas lines, and air-conditioning systems. Copper pipes maintain performance under varying temperature conditions and ensure leak-proof operation.

PVC pipes are lightweight, durable, and resistant to corrosion and chemicals. They are commonly used in water supply, drainage, and irrigation systems. PVC pipes offer smooth internal surfaces, ensuring efficient flow and minimal blockages. Easy to install and maintain, they reduce labor and installation costs. Suitable for residential, commercial, and agricultural applications. Their resistance to rust and scaling ensures long-term reliability.

CPVC pipes are designed to handle higher temperatures compared to standard PVC pipes. They are widely used for hot and cold water plumbing systems. CPVC offers excellent resistance to corrosion, scaling, and chemical reactions. These pipes maintain strength under pressure and elevated temperatures. Commonly used in residential, commercial, and industrial plumbing applications. CPVC pipes ensure long service life with minimal maintenance.

UPVC pipes are rigid plastic pipes known for their high strength and chemical resistance. They are widely used in water supply, drainage, and industrial fluid handling systems. UPVC pipes do not corrode, rust, or react with chemicals. Their smooth inner surface ensures high flow efficiency. Easy installation and low maintenance make them cost-effective. Suitable for underground and surface installations across various industries.

HDPE pipes are flexible, high-strength pipes known for their resistance to impact, chemicals, and environmental stress. They are widely used in water supply, gas distribution, sewage, and industrial piping systems. HDPE pipes offer leak-proof joints and long service life. Their flexibility allows installation in uneven terrain and seismic zones. Resistant to corrosion and UV exposure, they perform well in harsh conditions. Ideal for both underground and surface applications.

PEX pipes are flexible cross-linked polyethylene pipes used primarily in plumbing and heating systems. They offer excellent resistance to temperature fluctuations and pressure changes. PEX pipes are easy to install, reducing joint requirements and installation time. Commonly used for hot and cold water distribution. Their corrosion resistance ensures long-lasting performance. PEX pipes are suitable for residential and commercial plumbing systems.

Cast iron pipes are known for their strength, durability, and noise reduction properties. Widely used in drainage, sewage, and wastewater systems. These pipes offer excellent resistance to wear and high external loads. Cast iron pipes provide long service life in underground installations. Their rigidity ensures structural stability in heavy-duty applications. Commonly used in municipal and industrial infrastructure projects.

Ductile iron pipes combine the strength of cast iron with enhanced flexibility and impact resistance. They are widely used in water supply, sewage, and industrial piping systems. These pipes withstand high pressure and external loads effectively. Ductile iron pipes offer excellent corrosion resistance with proper lining and coating. Suitable for underground and heavy-duty infrastructure projects. Their durability ensures reliable performance over decades.

Water supply pipes are designed to ensure safe, reliable, and uninterrupted transportation of potable and non-potable water. These pipes must offer excellent corrosion resistance to prevent contamination and ensure long-term water quality. They are manufactured to withstand varying pressure conditions in residential, commercial, and industrial distribution networks. Smooth internal surfaces help maintain consistent flow rates and reduce friction losses. Water supply pipes are used in municipal systems, buildings, and industrial plants. Durability and leak-proof performance are critical to minimize maintenance and water loss. Compliance with safety and hygiene standards makes them suitable for drinking water applications.

Gas pipelines are engineered for the safe transportation of natural gas, LPG, and other industrial gases. These pipelines must withstand high pressure and temperature variations while maintaining structural integrity. Strong materials and secure joints are essential to prevent leakage and ensure operational safety. Gas pipelines are widely used in industrial plants, commercial facilities, and distribution networks. Corrosion resistance and pressure tolerance are critical design factors. These pipelines are installed following strict safety and regulatory standards. Reliable gas pipelines ensure continuous energy supply with minimal risk.

Steam pipes are used to transport high-temperature and high-pressure steam in industrial processes. These pipes are designed to withstand thermal expansion, pressure fluctuations, and extreme operating conditions. Commonly used in power plants, refineries, and manufacturing units, steam pipes ensure efficient energy transfer. High mechanical strength and heat resistance are essential for safe operation. Proper insulation is often used to reduce heat loss and improve efficiency. Steam pipes must maintain structural stability over long service periods. They play a vital role in industrial heating and power generation systems.

Fire-fighting pipes are critical safety components designed for emergency water supply during fire incidents. These pipes must deliver high water pressure and volume instantly and reliably. Used in buildings, industrial facilities, and infrastructure projects, they form the backbone of fire protection systems. Corrosion resistance and mechanical strength ensure long-term readiness. Fire-fighting pipelines are designed to comply with fire safety regulations and standards. Their durability and reliability are crucial for effective fire suppression. These systems help protect life, property, and assets.

Chemical transfer pipes are designed to handle aggressive, corrosive, and hazardous chemicals safely. These pipes must resist chemical reactions, leakage, and degradation over time. Used in chemical plants, pharmaceutical units, and industrial processing facilities, they ensure safe material movement. High chemical resistance and joint integrity are essential for operational safety. These pipelines help prevent contamination and environmental hazards. Proper material selection ensures compatibility with various chemicals. Chemical transfer pipes play a critical role in maintaining process safety and efficiency.

Drainage and sewer pipes are designed to efficiently transport wastewater and sewage from residential, commercial, and industrial facilities. These pipes must withstand continuous flow, external loads, and corrosive waste materials. Smooth internal surfaces help prevent blockages and ensure efficient discharge. Drainage pipes are commonly used in underground installations and municipal networks. Durability and leak resistance are key to preventing environmental contamination. These pipes support hygienic waste management systems. Proper installation ensures long-term performance with minimal maintenance.

Elbows are essential pipe fittings used to change the direction of fluid flow within a piping system. Available in 45°, 90°, and 180° angles, they help design compact and efficient pipeline layouts. Elbows are manufactured to withstand high pressure and temperature conditions. They ensure smooth directional changes with minimal flow resistance. Widely used in industrial, commercial, and infrastructure piping networks. Elbows are critical in systems where space constraints require directional flexibility. Properly designed elbows reduce stress concentration and enhance pipeline longevity.

Tees are pipe fittings used to divide or combine fluid flow within a pipeline. Equal tees distribute flow evenly in all directions, while reducing tees connect pipes of different diameters. These fittings are widely used in branching pipelines across industries. Tees maintain balanced flow distribution and system efficiency. Manufactured for strength and pressure resistance, they perform reliably under demanding conditions. Common applications include water supply, gas lines, and industrial process piping. Tees play a crucial role in multi-line pipeline systems.

Reducers are fittings used to connect pipes of different diameters while maintaining flow continuity. Concentric reducers align centrally and are commonly used in vertical piping systems. Eccentric reducers maintain a flat side, preventing air or fluid accumulation in horizontal pipelines. Reducers help control flow velocity and pressure within systems. They are widely used in process piping, pump connections, and industrial pipelines. Proper reducer selection improves system efficiency and reduces turbulence. These fittings ensure smooth transitions between pipe sizes.

Couplings are used to connect two pipes of the same diameter in a straight line. They provide a secure and leak-proof joint between pipe sections. Couplings are commonly used in repair, extension, and modification of pipelines. Designed for easy installation, they reduce downtime during maintenance. These fittings are suitable for both permanent and temporary piping connections. Couplings ensure structural continuity and system integrity. They are widely used across plumbing, industrial, and utility piping systems.

Unions are detachable pipe fittings designed to allow easy assembly and disassembly of piping systems. Unlike couplings, unions enable maintenance without cutting pipes. They are commonly used in pipelines requiring frequent inspection or replacement. Unions provide secure, leak-proof connections under pressure. Widely used in plumbing, industrial, and mechanical systems. Their design improves serviceability and reduces maintenance time. Unions enhance operational flexibility in complex piping networks.

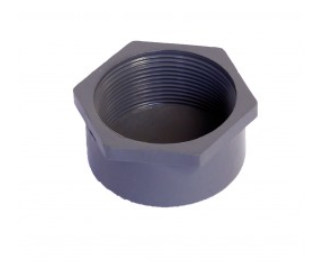

Caps and plugs are used to close the ends of pipes to stop fluid flow. Caps cover the external pipe end, while plugs seal internal pipe threads. These fittings are essential for pipeline termination, pressure testing, and future expansion provisions. Caps and plugs protect pipelines from contamination and damage. They are used across industrial, plumbing, and utility piping systems. Designed to withstand pressure, they ensure system safety and reliability. These fittings support both temporary and permanent closures.

Nipples are short pipe sections with threaded ends used to connect two fittings or components. They provide flexibility in spacing and alignment within piping systems. Nipples are widely used in compact installations and equipment connections. Available in various lengths and thread types, they support customization. These fittings ensure secure and leak-proof connections. Nipples are commonly used in plumbing, industrial, and mechanical applications. Their simplicity makes them essential components in pipeline assemblies.

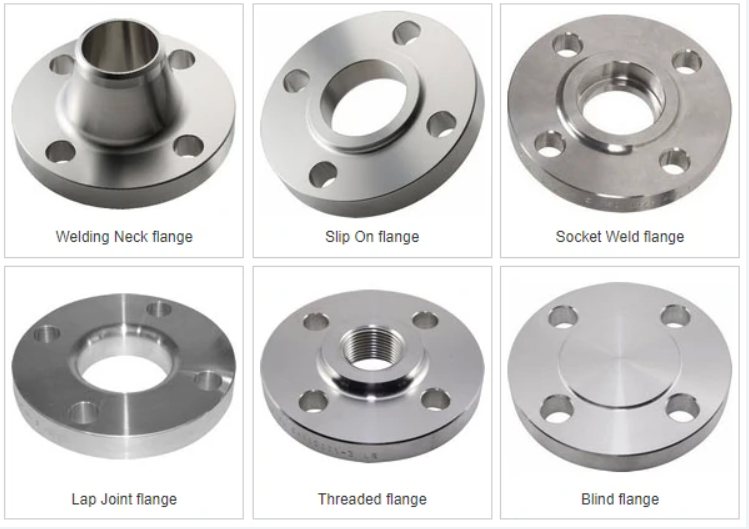

Flanges are pipe fittings used to connect pipes, valves, pumps, and equipment through bolted joints. Types include Weld Neck, Slip-On, Blind, Socket Weld, and Threaded flanges. Flanged connections allow easy assembly, inspection, and maintenance. They are designed to withstand high pressure, temperature, and mechanical stress. Widely used in industrial plants, refineries, and power stations. Flanges ensure strong sealing and alignment in piping systems. Their versatility makes them critical for heavy-duty applications.

Stub ends are pipe fittings used with lap joint flanges to create flexible flange connections. They allow easy alignment and rotation during installation. Stub ends are commonly used in systems requiring frequent dismantling. They reduce wear on flanges and improve joint longevity. Widely used in stainless steel and industrial piping systems. Stub ends support smooth flow and reliable sealing. They are ideal for applications where maintenance accessibility is important.

Plastic elbows are used to change the direction of flow in piping systems while maintaining smooth fluid movement. These fittings help design compact and efficient pipeline layouts in constrained spaces. Manufactured for durability, they offer excellent resistance to corrosion, chemicals, and moisture. Plastic elbows reduce friction losses and minimize stress on pipelines. Widely used in water supply, drainage, and industrial piping systems. Their lightweight nature allows easy handling and installation. Suitable for both residential and commercial applications. They ensure long-term leak-free performance when properly installed.

Plastic tees are fittings used to divide or combine flow within a pipeline system. They allow branching of pipelines without compromising flow efficiency. Tees are commonly used in plumbing, irrigation, and industrial fluid distribution systems. Manufactured with precision, they ensure secure and leak-proof connections. Plastic tees offer resistance to chemicals and corrosion. Available in equal and reducing configurations to suit different pipe sizes. Their smooth internal surface ensures consistent flow. These fittings support flexible and scalable piping layouts.

Plastic reducers are used to connect pipes of different diameters within a piping system. They help control flow velocity and pressure transitions efficiently. Reducers ensure smooth flow without turbulence or sudden pressure loss. Widely used in water supply, drainage, and industrial piping networks. These fittings provide excellent chemical resistance and durability. Plastic reducers are lightweight and easy to install. Suitable for both vertical and horizontal installations. They help optimize system performance and longevity.

Plastic end caps are used to seal the open ends of pipes securely. They prevent leakage, contamination, and accidental discharge of fluids. End caps are essential for pipeline termination, pressure testing, and future expansion points. Manufactured for strength and durability, they withstand internal pressure effectively. Commonly used in plumbing, drainage, and industrial piping systems. Plastic end caps resist corrosion and chemical attack. They provide a clean and safe pipe closure solution. Suitable for both temporary and permanent applications.

Plastic couplers are fittings used to join two pipes of the same diameter in a straight line. They provide a strong, leak-proof connection between pipe sections. Couplers are commonly used for pipeline extensions, repairs, and modifications. Lightweight and easy to install, they reduce installation time and effort. These fittings offer excellent resistance to rust, corrosion, and chemicals. Widely used in plumbing, irrigation, and industrial applications. Plastic couplers ensure long-term system integrity. They support smooth and continuous flow.

Plastic saddles are fittings used to create branch connections on existing pipelines without cutting the pipe completely. They are commonly used in water distribution and irrigation systems. Saddles allow quick and efficient tapping of pipelines. Designed for secure clamping, they ensure leak-proof connections. Plastic saddles offer corrosion resistance and durability. Suitable for underground and surface installations. They minimize downtime during system expansion. Saddles provide a cost-effective solution for pipeline branching.

Solvent weld fittings are designed to create permanent, leak-proof joints using chemical bonding. The solvent softens the pipe and fitting surfaces, forming a strong molecular bond. These fittings are widely used in PVC and CPVC piping systems. Solvent weld joints provide excellent pressure-handling capability. Common applications include water supply, drainage, and chemical piping systems. These fittings ensure long service life with minimal maintenance. Proper installation results in a joint as strong as the pipe itself. Ideal for permanent piping installations.

Compression fittings are mechanical joints used to connect pipes without welding or solvents. They provide quick and secure connections using compression rings and nuts. These fittings are widely used in water supply and repair applications. Compression fittings allow easy installation and disassembly. They offer reliable sealing under moderate pressure conditions. Suitable for both temporary and permanent installations. These fittings reduce installation time and skill requirements. Ideal for maintenance and retrofit projects.

Gate valves are primarily used to start or stop the flow of fluid in a pipeline. They operate by lifting a gate out of the flow path, allowing unobstructed flow when fully open. These valves cause very low pressure drop, making them suitable for long pipeline runs. Gate valves are not recommended for throttling applications as partial opening can damage the gate. They are widely used in water supply systems, oil and gas pipelines, and industrial process lines. Their simple design ensures durability and reliable performance. Available in various materials, they can handle high pressure and temperature conditions. Gate valves are ideal where infrequent operation is required.

Globe valves are designed specifically for regulating and throttling fluid flow. Their internal structure allows precise control over flow rate and pressure. Unlike gate valves, globe valves can be operated in partially open positions without damage. They are commonly used in steam systems, fuel oil lines, and cooling water systems. Globe valves provide excellent shut-off capability when closed. Though they cause higher pressure drop, they offer superior flow control accuracy. These valves are suitable for applications requiring frequent operation. Their robust construction ensures long-term reliability in industrial environments.

Ball valves use a rotating ball with a bore to control fluid flow efficiently. They offer quick quarter-turn operation, allowing fast opening and closing. Ball valves provide tight shut-off and minimal leakage, making them highly reliable. They are suitable for water, gas, chemicals, and oil applications. Due to their simple design, they require very low maintenance. Ball valves allow smooth flow with minimal pressure loss. They are available in full bore and reduced bore designs. Their durability makes them ideal for high-pressure and high-temperature systems.

Butterfly valves control fluid flow using a rotating disc mounted on a central shaft. They are compact, lightweight, and require less installation space compared to other valves. These valves are ideal for large-diameter pipelines and high-volume flow applications. Butterfly valves allow quick operation with minimal effort. They are widely used in water treatment plants, HVAC systems, and fire-fighting lines. Their design supports both on-off and throttling operations. Butterfly valves offer cost-effective solutions for large systems. They provide good sealing and long service life.

Check valves, also known as Non-Return Valves, allow fluid to flow in only one direction. They automatically prevent backflow without manual operation. These valves protect pumps, compressors, and pipelines from damage caused by reverse flow. Check valves are widely used in water supply, oil, gas, and chemical pipelines. They operate based on fluid pressure and flow direction. Available in swing, lift, and spring-loaded designs, they suit different applications. Check valves ensure system safety and efficiency. Their simple mechanism ensures reliable performance with minimal maintenance.

Plug valves control flow using a cylindrical or tapered plug with a passage. They provide quick on-off operation with a quarter turn. These valves are known for tight sealing and leak-proof performance. Plug valves are suitable for handling slurries, viscous fluids, and corrosive media. Their simple design ensures easy operation and maintenance. They are commonly used in chemical processing and oil industries. Plug valves offer low flow resistance when fully open. Their durability makes them suitable for demanding industrial conditions.

Diaphragm valves use a flexible diaphragm to control fluid flow. They provide excellent sealing and are ideal for handling corrosive and abrasive fluids. These valves prevent contamination, making them suitable for pharmaceutical and food industries. Diaphragm valves offer smooth flow control and tight shut-off. They are easy to maintain due to simple internal construction. These valves are commonly used in chemical and wastewater treatment plants. Diaphragm valves perform well in low-pressure applications. Their hygienic design supports clean and safe operations.

Needle valves are designed for precise flow control in low-flow applications. They use a slender, tapered needle to regulate flow accurately. These valves are commonly used in instrumentation and pressure control systems. Needle valves allow gradual and controlled opening and closing. They are ideal for gases and liquids requiring fine adjustment. Their design supports high-pressure applications. Needle valves ensure stable flow and pressure regulation. They are widely used in laboratories and industrial monitoring systems.

Control valves are critical components used to regulate flow, pressure, temperature, and liquid levels in industrial systems. They automatically adjust their position based on signals received from controllers or sensors. These valves ensure precise process control, improving efficiency and product quality. Control valves are widely used in oil & gas, power plants, chemical industries, and water treatment facilities. They help maintain stable operating conditions under varying loads. Available in pneumatic, electric, and hydraulic actuation types, they suit diverse applications. Control valves reduce energy losses and system fluctuations. Their accurate modulation ensures safety and consistent performance. Designed for continuous operation, they are built for durability and reliability. Proper control valve selection enhances overall plant productivity.

Pressure reducing valves are designed to automatically reduce high inlet pressure to a safe and constant outlet pressure. They protect downstream pipelines, equipment, and fixtures from damage caused by excessive pressure. PRVs maintain stable pressure regardless of fluctuations in upstream supply. These valves are commonly used in water supply systems, steam lines, and industrial processes. They help improve system efficiency and extend equipment life. Pressure reducing valves reduce water hammer and pressure-related failures. They operate without external power, using internal spring and diaphragm mechanisms. PRVs ensure consistent flow performance. Their use improves safety and reduces maintenance costs. Ideal for residential, commercial, and industrial installations.

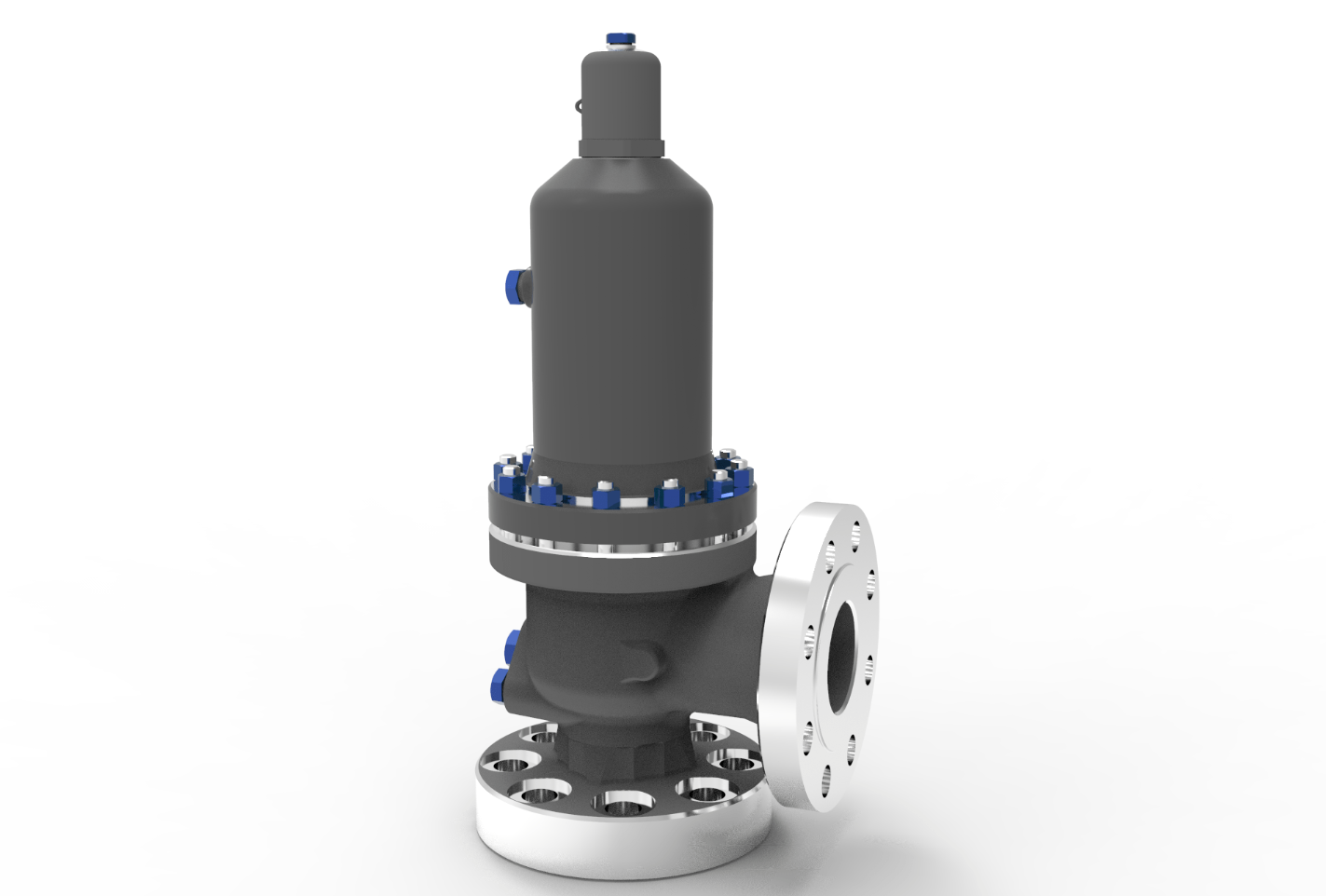

Pressure relief and safety valves are essential safety devices used to protect systems from overpressure conditions. They automatically release excess pressure when it exceeds a preset limit. These valves prevent equipment failure, explosions, and system damage. Widely used in boilers, pressure vessels, compressors, and pipelines. Safety valves operate instantly to ensure rapid pressure discharge. They play a crucial role in industrial safety compliance. Designed to handle extreme pressure conditions, they ensure reliable operation. Once pressure returns to normal, the valve reseats automatically. These valves help safeguard personnel and infrastructure. Mandatory in high-pressure industrial applications.

Solenoid valves are electrically operated valves used for automatic flow control. They open or close in response to an electrical signal, enabling fast and precise operation. Commonly used in automation systems, irrigation, HVAC, and fluid control applications. Solenoid valves offer excellent response time and reliable performance. They are suitable for air, water, oil, and gas applications. Available in normally open and normally closed configurations. These valves simplify remote operation and system automation. Compact design allows easy installation in tight spaces. Solenoid valves improve process efficiency and control accuracy. Ideal for modern automated industrial systems.

Foot valves are installed at the suction end of pumps to maintain prime and prevent backflow. They allow fluid to flow in one direction while stopping reverse flow when the pump is off. Commonly used in water supply, irrigation, and pumping systems. Foot valves help improve pump efficiency and reduce startup time. They are usually equipped with strainers to prevent debris entry. These valves protect pumps from dry running and damage. Made from durable materials for long service life. Foot valves reduce maintenance requirements. Suitable for wells, tanks, and reservoirs. Essential for smooth pump operation.

Float valves automatically control liquid levels in tanks and reservoirs. They operate based on the movement of a float that rises and falls with the liquid level. When the desired level is reached, the valve shuts off the flow. Commonly used in overhead tanks, storage tanks, and industrial reservoirs. Float valves prevent overflow and water wastage. They ensure consistent liquid levels without manual intervention. Simple mechanical operation ensures reliability. These valves are cost-effective and easy to install. Suitable for water and non-corrosive liquids. Widely used in residential, commercial, and industrial applications.

Cast iron valves are widely used in low to medium pressure applications. They offer good strength, rigidity, and cost-effectiveness for general industrial use. Commonly used in water supply, drainage, and fire-fighting systems. Cast iron provides excellent wear resistance and long service life. These valves are easy to manufacture and maintain. They are suitable for non-corrosive fluids and moderate temperatures. Cast iron valves are preferred where budget-friendly solutions are required. Their robust structure ensures stable operation. Not ideal for high-impact or high-pressure applications. Best suited for municipal and infrastructure projects.

Ductile iron valves offer higher strength and flexibility compared to cast iron. They can withstand higher pressure and mechanical stress. Widely used in water distribution, sewage systems, and industrial pipelines. Ductile iron provides excellent impact resistance and durability. These valves are less prone to cracking under load. They offer long-term performance in demanding environments. Often coated with epoxy for corrosion protection. Suitable for both underground and above-ground installations. Ductile iron valves combine strength with cost efficiency. Ideal for heavy-duty applications.

Brass valves are commonly used in plumbing and low-pressure applications. They offer good corrosion resistance, especially in water systems. Brass provides excellent machinability and smooth operation. These valves are widely used in residential and commercial plumbing. They ensure leak-free performance and long service life. Brass valves are suitable for hot and cold water applications. They offer good resistance to rust and scaling. Compact and easy to install, they are widely preferred. Brass valves provide reliable flow control. Ideal for household and light industrial use.

Bronze valves offer superior corrosion resistance compared to brass. They are ideal for marine, seawater, and chemical applications. Bronze material provides excellent strength and durability. These valves perform well in harsh and corrosive environments. Widely used in shipbuilding and coastal installations. Bronze valves resist dezincification and wear. They ensure smooth operation over long periods. Suitable for both water and oil applications. Bronze valves offer reliable sealing performance. Preferred for premium and critical applications.

Carbon steel valves are designed for high-pressure and high-temperature applications. They provide excellent mechanical strength and durability. Commonly used in oil & gas, steam, and power plants. Carbon steel can handle extreme operating conditions. These valves offer good resistance to pressure and thermal stress. Widely used in industrial process pipelines. Carbon steel valves are suitable for non-corrosive or mildly corrosive fluids. They ensure long service life with proper maintenance. Available in various industrial standards. Ideal for heavy-duty industrial systems.

Stainless steel valves offer excellent corrosion resistance and high strength. They are ideal for aggressive, corrosive, and hygienic applications. Widely used in chemical, pharmaceutical, food, and beverage industries. Stainless steel resists rust, oxidation, and chemical attack. These valves maintain performance under high pressure and temperature. They ensure clean and contamination-free flow. Stainless steel valves offer long operational life. Easy to clean and maintain. Suitable for both liquid and gas applications. Preferred for critical and high-purity systems.

PVC and UPVC valves are lightweight and corrosion-resistant. They are commonly used in water treatment, irrigation, and chemical pipelines. These materials resist rust, scaling, and chemical attack. PVC valves are suitable for low-pressure applications. UPVC valves offer higher strength and temperature resistance. Easy to install and cost-effective. These valves provide smooth flow with minimal friction loss. Ideal for corrosive fluids and outdoor installations. Require minimal maintenance. Widely used in residential, commercial, and industrial piping systems.