A Desalter is an essential part of crude oil refining operations, designed to remove salts, water, and suspended impurities from crude oil before it enters the atmospheric distillation unit. These contaminants, if not removed, can cause severe corrosion, fouling, and catalyst deactivation in downstream processing units.

MGV’s advanced electrostatic desalting systems utilize a high-voltage electric field to coalesce and separate water droplets from crude oil efficiently. The process ensures optimal dehydration and desalting with minimal chemical usage, providing cleaner feedstock for improved plant reliability and longer equipment life.

Our desalters are engineered for high performance, low maintenance, and flexible operation across a wide range of crude qualities. Built with corrosion-resistant materials, automatic control systems, and safety interlocks, they ensure continuous and safe operation even under demanding refinery conditions.

Whether for single-stage or dual-stage desalting, MGV’s solutions guarantee reduced maintenance downtime, extended exchanger run life, and improved environmental compliance. Designed with a strong focus on sustainability and energy efficiency, our desalters help refineries minimize water consumption and reduce waste disposal costs — delivering both operational excellence and economic value.

A Heat Exchanger is a critical component in industrial processes, facilitating efficient heat transfer between two or more fluids without direct contact. MGV designs and manufactures a comprehensive range of heat exchangers tailored for oil & gas, petrochemical, power, and water treatment industries.

Our heat exchangers are engineered to deliver superior thermal performance, mechanical integrity, and long service life. Using cutting-edge design software and advanced fabrication methods, MGV ensures precise temperature control and optimized energy recovery in every unit.

We offer multiple configurations — including shell & tube, plate, finned-tube, and air-cooled exchangers — each designed for specific operating pressures and temperature ranges. All units are manufactured in compliance with ASME and TEMA standards to ensure unmatched reliability.

With corrosion-resistant materials, easy maintenance access, and custom-built designs, our heat exchangers enhance process efficiency, reduce operational costs, and minimize energy loss. From refineries to chemical plants, MGV heat exchangers play a vital role in maintaining operational stability, performance, and sustainability across industries.

Induced Gas Floatation (IGF) Units are advanced water treatment systems designed to efficiently separate oil, grease, and suspended solids from produced water. MGV’s IGF units leverage micro-bubble aeration technology, where fine gas bubbles attach to oil droplets and suspended solids, allowing them to float to the surface for easy removal.

Our IGF systems are widely used in oil & gas production facilities, refineries, and petrochemical plants, offering high separation efficiency and minimal maintenance requirements.

Built with corrosion-resistant materials and modular skid-mounted construction, these units provide durability and flexibility for both onshore and offshore applications. The system can operate continuously under varying feed conditions and is equipped with automatic controls for consistent performance.

MGV’s IGF units not only help industries comply with strict environmental discharge regulations but also ensure maximum recovery of reusable hydrocarbons. With optimized hydraulic flow design and minimal power consumption, they provide a sustainable, cost-effective solution for wastewater treatment and resource recovery — enabling industries to operate with greater efficiency, safety, and environmental responsibility.

A Demin (Demineralization) Plant is designed to produce ultra-pure water by removing dissolved salts and ionic impurities from raw or process water through ion exchange technology. At MGV, we specialize in delivering high-capacity demin plants that serve critical applications in power generation, refineries, chemical manufacturing, and pharmaceuticals.

Our systems utilize a combination of cation, anion, and mixed-bed resin units to ensure the highest purity levels, typically achieving conductivity as low as 0.1 µS/cm. These plants are fully automated and equipped with user-friendly control systems for precise operation, minimal downtime, and optimal regeneration cycles.

Built with high-quality vessels, corrosion-resistant internals, and advanced monitoring instruments, MGV’s demin plants offer superior performance, long service life, and reduced operational costs.

Whether for boiler feedwater, process requirements, or laboratory use, our demin plants ensure reliable water quality that meets the most stringent industry standards. Each system is designed for maximum efficiency, minimal chemical usage, and sustainability, helping industries achieve continuous operation with consistent output quality.

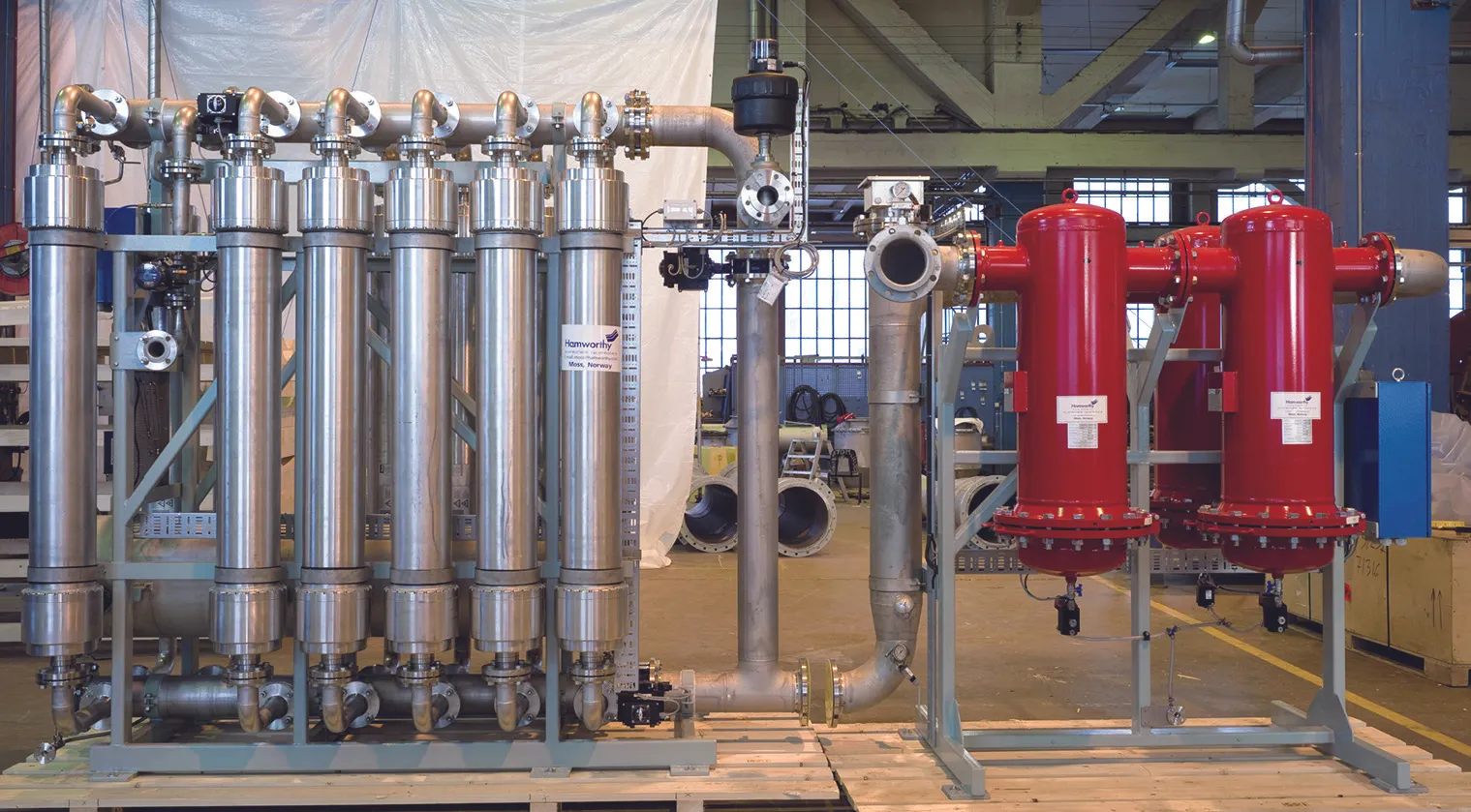

The Ultra Filtration (UF) Plant by MGV is an advanced membrane-based filtration system designed for the effective removal of suspended solids, colloids, bacteria, and organic matter from water and wastewater. It serves as a crucial pretreatment step for reverse osmosis (RO) and other high-purity water systems.

MGV’s UF systems employ hollow fiber or spiral wound membranes, offering consistent permeate quality even with fluctuating feed water conditions. The systems are fully automated with PLC-based control panels, ensuring easy operation, self-cleaning backwash cycles, and minimal manual intervention.

Ideal for use in municipal water treatment, industrial wastewater recycling, and food & beverage processing, these plants guarantee reduced fouling, lower maintenance costs, and longer membrane life.

Constructed with durable components and designed for scalability, our UF systems deliver long-term reliability, reduced operating costs, and environmental compliance. MGV’s UF plants embody the perfect balance of technology, efficiency, and sustainability, making them a preferred choice for industries seeking superior water treatment performance.

MGV’s Industrial Boilers are engineered for high efficiency, reliability, and longevity. Designed to generate steam or hot water for diverse industrial processes, our boilers are suitable for oil & gas, manufacturing, textile, chemical, and food industries.

We offer a complete range of fire-tube, water-tube, and packaged boilers with fully automatic controls for safe, easy, and efficient operation. MGV boilers are built from premium-grade materials, ensuring corrosion resistance and high pressure tolerance for long operational life.

With features such as low NOx burners, fuel flexibility, automatic feed systems, and high thermal efficiency, our boilers minimize fuel consumption while maintaining consistent performance.

Every unit undergoes rigorous testing and meets international quality standards like IBR and ASME. MGV’s focus on innovation ensures our boilers contribute to energy conservation, emission reduction, and sustainable operations — making them an ideal solution for industries seeking performance, reliability, and eco-friendly operation.

MGV’s Nitrogen Generators are advanced on-site gas generation systems designed to produce high-purity nitrogen using Pressure Swing Adsorption (PSA) or Membrane Separation Technology. These systems eliminate dependency on bulk nitrogen supply and reduce operating costs significantly.

Our nitrogen generators are ideal for oil & gas, chemical, pharmaceutical, food packaging, and electronics industries, offering purity levels up to 99.999%. The PSA technology uses high-quality carbon molecular sieves (CMS) to adsorb oxygen and deliver a continuous flow of nitrogen.

MGV’s generators are fully automated, energy-efficient, and compact in design, featuring intelligent control panels for real-time monitoring and performance optimization. They operate quietly, require minimal maintenance, and deliver consistent nitrogen output even in demanding conditions.

Each system is custom-built to meet client-specific requirements, ensuring reliability, efficiency, and safety in every application. By providing a steady, on-demand nitrogen supply, MGV’s solutions help industries reduce downtime, enhance productivity, and ensure long-term operational independence.